Join the "Roland Sampler Information Exchange" group on Facebook

Join the "Roland Sampler Information Exchange" group on Facebook

| If you find some of this DIY info useful, please consider donating a small amount. All donations are used for future DIY synth and sampler development. Thanks! |

|

Quick Links To S‑50 / S‑330 / S‑550 / S‑760 / W‑30 Information  GOTEK USB FLOPPY DRIVE EMULATOR ‑ The Modern Day 3.5" Floppy Disk Drive Replacement GOTEK USB FLOPPY DRIVE EMULATOR ‑ The Modern Day 3.5" Floppy Disk Drive Replacement

ZULUSCSI ‑ Considering Adding SCSI? Don't Think About It Anymore. Just Get a ZuluSCSI !!!!! ZULUSCSI ‑ Considering Adding SCSI? Don't Think About It Anymore. Just Get a ZuluSCSI !!!!!

S‑50 CONTROL JACK TEMPLATES ‑ High Resolution PDF Printouts To Make Things Easier S‑50 CONTROL JACK TEMPLATES ‑ High Resolution PDF Printouts To Make Things Easier

S‑50 NOISE, STATIC AND DISTORTION ISSUES ‑ It's The Relay Coil. Here Are Some Solutions S‑50 NOISE, STATIC AND DISTORTION ISSUES ‑ It's The Relay Coil. Here Are Some Solutions

S‑550 DISTORTED SOUND ‑ Connecting The S‑550 To Non‑Grounded Equipment Can Cause This S‑550 DISTORTED SOUND ‑ Connecting The S‑550 To Non‑Grounded Equipment Can Cause This

S‑550 MOUSE / RC‑100 ISSUES ‑ A Common Problem With The S‑550 S‑550 MOUSE / RC‑100 ISSUES ‑ A Common Problem With The S‑550

S‑550 NO SOUND OUTPUT OR SCRATCHY SOUND ‑ Also Happens With The S‑220 & MKS‑100 S‑550 NO SOUND OUTPUT OR SCRATCHY SOUND ‑ Also Happens With The S‑220 & MKS‑100

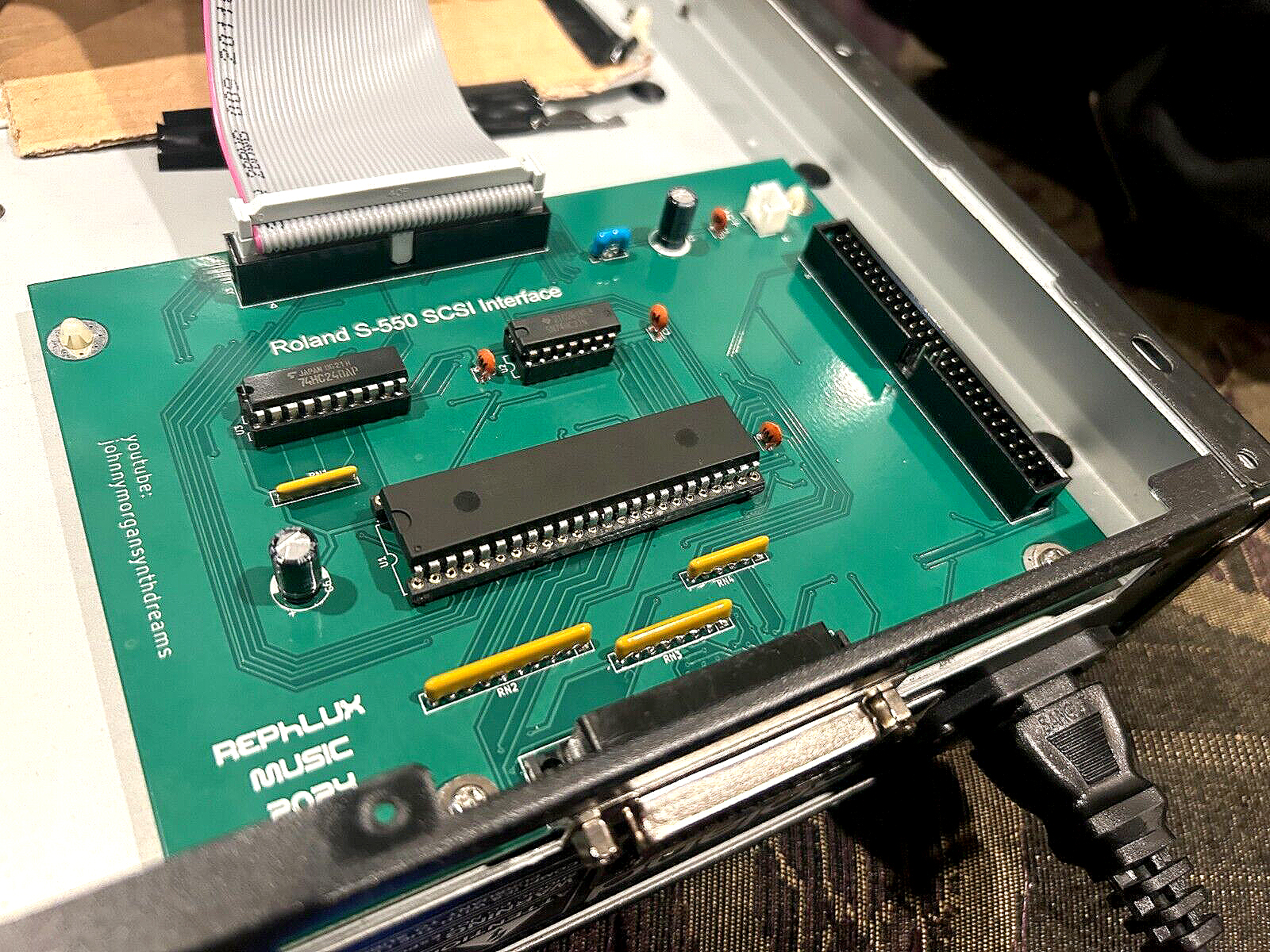

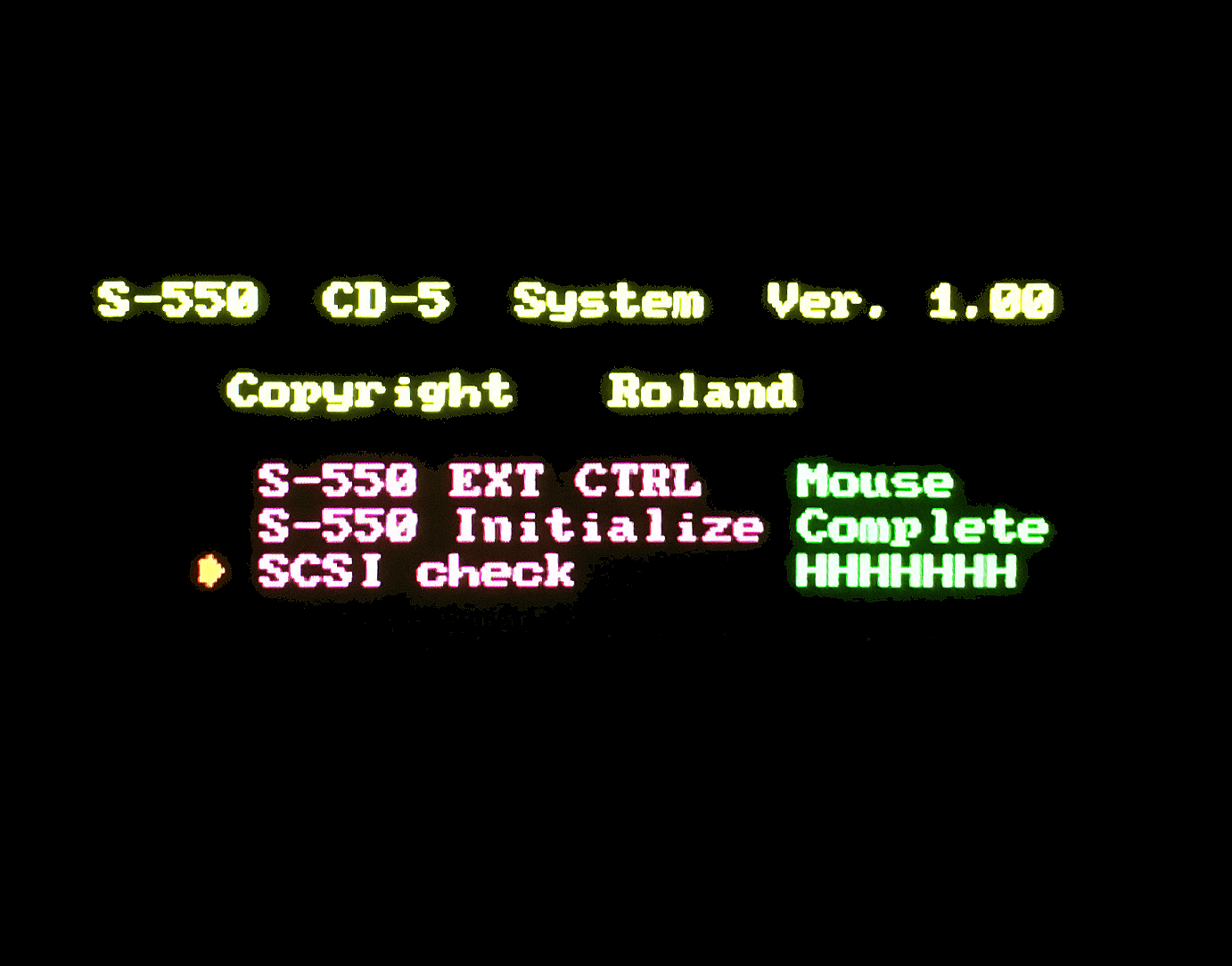

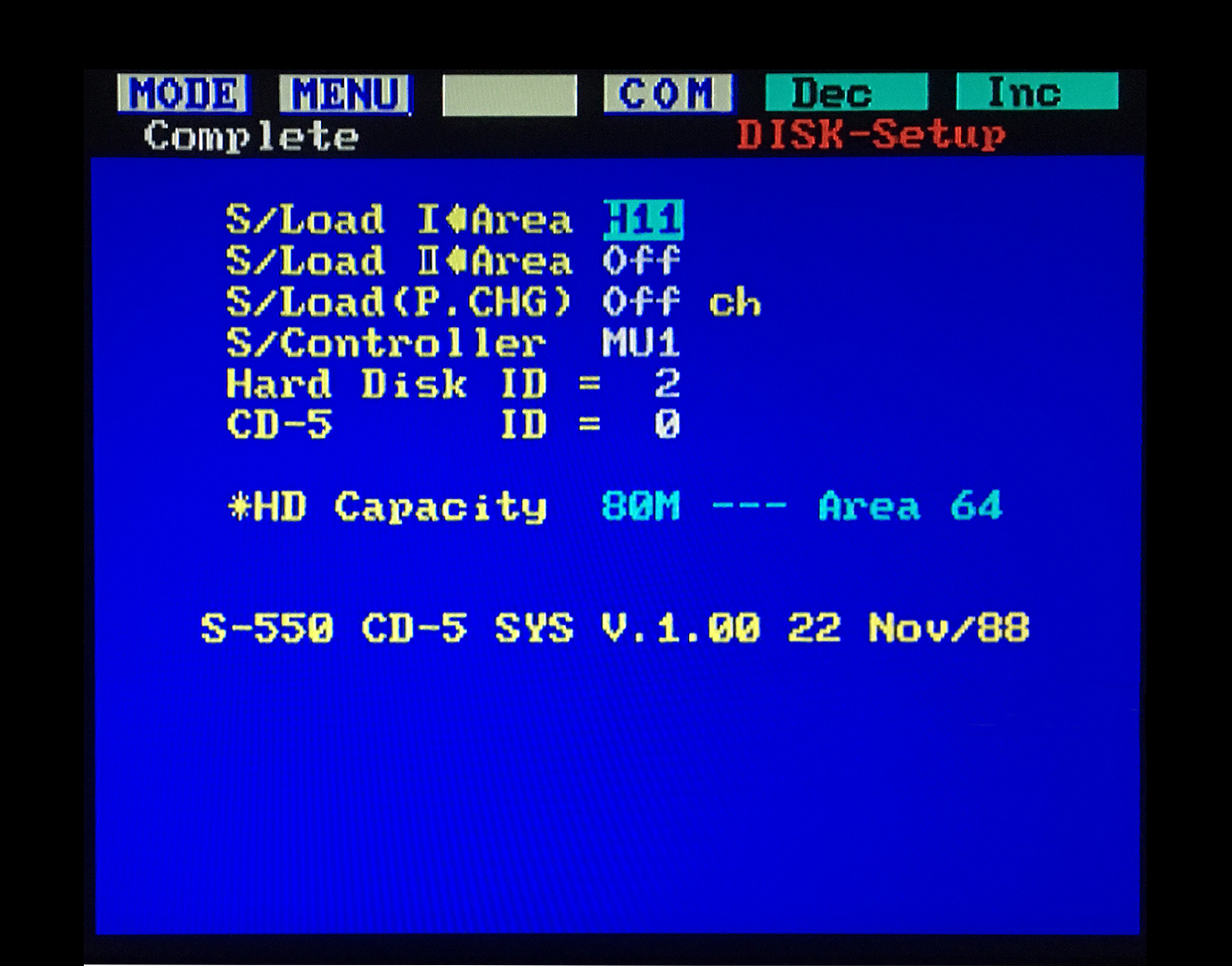

S-550 BOOT SETUPS FOR A HARD DRIVE OR SCSI2SD DEVICE ‑ S‑550 Boot Configurations S-550 BOOT SETUPS FOR A HARD DRIVE OR SCSI2SD DEVICE ‑ S‑550 Boot Configurations

W‑30 SCSI ‑ The KW‑30 SCSI IC Chip Upgrade. Simple, Cheap & Powerful W‑30 SCSI ‑ The KW‑30 SCSI IC Chip Upgrade. Simple, Cheap & Powerful

W‑30 EPROMS ‑ W‑30 Firmware Info W‑30 EPROMS ‑ W‑30 Firmware Info

W‑30 LCD REPLACEMENT ‑ Stop that whining banshee from Hell!!! W‑30 LCD REPLACEMENT ‑ Stop that whining banshee from Hell!!!

W‑30 CUSTOM WAVE ROMS ‑ Replace The Default Wave ROM's With Better Samples W‑30 CUSTOM WAVE ROMS ‑ Replace The Default Wave ROM's With Better Samples

W‑30 CONTROL JACK TEMPLATES ‑ High Resolution PDF Printouts To Make Things Easier W‑30 CONTROL JACK TEMPLATES ‑ High Resolution PDF Printouts To Make Things Easier

W‑30 REAL‑TIME FILTER CONTROL ‑ Take Your W‑30 To The Next Level W‑30 REAL‑TIME FILTER CONTROL ‑ Take Your W‑30 To The Next Level

W‑30 "COOL BLUE" LCD BACKLIGHT ‑ Your W‑30 Display Shines Again!!! W‑30 "COOL BLUE" LCD BACKLIGHT ‑ Your W‑30 Display Shines Again!!!

W‑30 LCD CONTRAST POT REPLACEMENT ‑ An Easy Fix For This Common Problem W‑30 LCD CONTRAST POT REPLACEMENT ‑ An Easy Fix For This Common Problem

W‑30 JOG WHEEL AND ENCODER REPLACEMENT/REPAIR ‑ Several Options For The W‑30 W‑30 JOG WHEEL AND ENCODER REPLACEMENT/REPAIR ‑ Several Options For The W‑30

W-30 BOOT SETUPS FOR A HARD DRIVE OR SCSI2SD DEVICE ‑ W‑30 Boot Configurations W-30 BOOT SETUPS FOR A HARD DRIVE OR SCSI2SD DEVICE ‑ W‑30 Boot Configurations

S‑760 LCD INFO ‑ A Troublesome Issue With The S‑760 S‑760 LCD INFO ‑ A Troublesome Issue With The S‑760

LOADING AKAI CD-ROM's ON THE S-760 - Step By Step Procedures LOADING AKAI CD-ROM's ON THE S-760 - Step By Step Procedures

S‑760 ENCODER REPLACEMENT/REPAIR ‑ A Few Options For The S‑760 S‑760 ENCODER REPLACEMENT/REPAIR ‑ A Few Options For The S‑760

AKAI CD-ROM COMPATIBILITY UTILITY FOR THE S-760 - Web Based Utility AKAI CD-ROM COMPATIBILITY UTILITY FOR THE S-760 - Web Based Utility

S-760 MEDICAL GRADE POWER SUPPLY REPLACEMENT - A Quality Repair For A Broken PSU S-760 MEDICAL GRADE POWER SUPPLY REPLACEMENT - A Quality Repair For A Broken PSU

S-760 BOOT SETUPS FOR A HARD DRIVE OR SCSI2SD DEVICE ‑ S‑760 Boot Configurations S-760 BOOT SETUPS FOR A HARD DRIVE OR SCSI2SD DEVICE ‑ S‑760 Boot Configurations

SP-700 LCD DIY REPLACEMENT ‑ An Inexpensive Modern Day LCD Replacement SP-700 LCD DIY REPLACEMENT ‑ An Inexpensive Modern Day LCD Replacement

LOADING AKAI CD-ROM's ON THE SP-700 - Step By Step Procedures LOADING AKAI CD-ROM's ON THE SP-700 - Step By Step Procedures

SP-700 2-PRONG CABLE TO 3-PRONG CABLE DIY - A super easy mod. Play it safe! SP-700 2-PRONG CABLE TO 3-PRONG CABLE DIY - A super easy mod. Play it safe!

AKAI CD-ROM COMPATIBILITY UTILITY FOR THE SP-700 - Web Based Utility AKAI CD-ROM COMPATIBILITY UTILITY FOR THE SP-700 - Web Based Utility

SCSI2SD ‑ Virtual SCSI Access for the S-660, W-30 and S-760 SCSI2SD ‑ Virtual SCSI Access for the S-660, W-30 and S-760

SCSI CD‑ROM ‑ Aaah Yes...... The Elusive External SCSI CD‑ROM SCSI CD‑ROM ‑ Aaah Yes...... The Elusive External SCSI CD‑ROM

SCSI ZIP DRIVE ‑ Extra Sample Storage In A Major Way SCSI ZIP DRIVE ‑ Extra Sample Storage In A Major Way

SCSI HARD DRIVE ‑ Even More Extra Sample Storage SCSI HARD DRIVE ‑ Even More Extra Sample Storage

CD-5 SCSI CD‑ROM ‑ Roland's Mysterious And Very Annoying Proprietary SCSI CD‑ROM CD-5 SCSI CD‑ROM ‑ Roland's Mysterious And Very Annoying Proprietary SCSI CD‑ROM

ULTRASCSI HARD DRIVE ‑ UltraSCSI? 1980's Sampler? Yes... It is possible! ULTRASCSI HARD DRIVE ‑ UltraSCSI? 1980's Sampler? Yes... It is possible!

BOOT THE SAMPLER FROM A HARD DRIVE OR SCSI2SD DEVICE ‑ S‑550, W‑30 & S‑760 Configurations BOOT THE SAMPLER FROM A HARD DRIVE OR SCSI2SD DEVICE ‑ S‑550, W‑30 & S‑760 Configurations

"dd" ‑ Mac Support For Creating And Archiving 3.5" Floppy Disks And Disk Image Files "dd" ‑ Mac Support For Creating And Archiving 3.5" Floppy Disks And Disk Image Files

SPARES ‑ Roland Spare Parts Cross Reference List SPARES ‑ Roland Spare Parts Cross Reference List

MONITOR SHARING ‑ How To Share 1 Monitor With 2 Or More Samplers MONITOR SHARING ‑ How To Share 1 Monitor With 2 Or More Samplers

OLD RGB MONITORS ‑ DIY Instructions For An Ancient Atari Monitor Cable Adapter OLD RGB MONITORS ‑ DIY Instructions For An Ancient Atari Monitor Cable Adapter

FUSE REPLACEMENTS ‑ A Fuse Reference Page For Roland Samplers And Synths FUSE REPLACEMENTS ‑ A Fuse Reference Page For Roland Samplers And Synths

ODDBALL POWER CORD - Get Rid Of That Boondoggle! ODDBALL POWER CORD - Get Rid Of That Boondoggle!

3.5" FDD REPLACEMENTS ‑ Inexpensive Replacement Drives For The S‑50, S‑550, S‑760 and W‑30 3.5" FDD REPLACEMENTS ‑ Inexpensive Replacement Drives For The S‑50, S‑550, S‑760 and W‑30

MOUSE AND RC‑100 ISSUES ‑ A Common Problem With The S‑330, S‑550, S‑750 And S‑770 MOUSE AND RC‑100 ISSUES ‑ A Common Problem With The S‑330, S‑550, S‑750 And S‑770

THE EV‑5 EXPRESSION PEDAL ‑ Build An EV‑5 Hand Controller For A Fraction Of The Cost THE EV‑5 EXPRESSION PEDAL ‑ Build An EV‑5 Hand Controller For A Fraction Of The Cost

USING A NON‑ROLAND MOUSE ‑ How To Use A PS/2 Or USB Mouse With The S‑550, S‑330 Or S‑7xx USING A NON‑ROLAND MOUSE ‑ How To Use A PS/2 Or USB Mouse With The S‑550, S‑330 Or S‑7xx

TACT SWITCH REPLACEMENTS S‑50, S‑7xx & W‑30 Button Madness TACT SWITCH REPLACEMENTS S‑50, S‑7xx & W‑30 Button Madness

MAIN PCB AND POWER SUPPLY ‑ Boards Used For Testing These DIY's MAIN PCB AND POWER SUPPLY ‑ Boards Used For Testing These DIY's

SDISKW, OMNIFLOP or "dd" ??? ‑ Disk Image Utilities For Copying/Creating/Archiving Sample Disks SDISKW, OMNIFLOP or "dd" ??? ‑ Disk Image Utilities For Copying/Creating/Archiving Sample Disks

RGB TO VGA VIDEO CONVERTER ‑ $19 Board For Connecting A Color Monitor To The S‑Series Samplers RGB TO VGA VIDEO CONVERTER ‑ $19 Board For Connecting A Color Monitor To The S‑Series Samplers

MOUNTING *.ISO DISK IMAGE FILES ‑ How To Mount Virtual CD-ROM's MOUNTING *.ISO DISK IMAGE FILES ‑ How To Mount Virtual CD-ROM's

RGB VIDEO OUTPUT NOT WORKING ‑ S‑550, S‑330 And S‑7xx Samplers Use The Same Fuse For Video Circuit Protection RGB VIDEO OUTPUT NOT WORKING ‑ S‑550, S‑330 And S‑7xx Samplers Use The Same Fuse For Video Circuit Protection

MAGAZINE REVIEWS, ARTICLES & ADS - Several Excellent Reviews & Articles With Useful Operating Tips & Tricks MAGAZINE REVIEWS, ARTICLES & ADS - Several Excellent Reviews & Articles With Useful Operating Tips & Tricks

FAVORITE DIY TOOLS AND DIY VENDORS ‑ Tips For DIY Freaks Who Like To Save $$$

FAVORITE DIY TOOLS AND DIY VENDORS ‑ Tips For DIY Freaks Who Like To Save $$$

GOTEK USB FLOPPY DRIVE EMULATOR (USB/FDE) ‑ A Modern 3.5" Floppy Disk Drive Replacement GOTEK USB FLOPPY DRIVE EMULATOR (USB/FDE) ‑ A Modern 3.5" Floppy Disk Drive Replacement

FIRMWARE AND EPROMS FOR THE S‑550 AND W‑30 ‑ Wanna Burn One? FIRMWARE AND EPROMS FOR THE S‑550 AND W‑30 ‑ Wanna Burn One?

BURNING *.MDX, *.ISO, *.BIN & *.CUE SAMPLE LIBRARY FILES TO CD‑ROM ‑ Burning Down The House BURNING *.MDX, *.ISO, *.BIN & *.CUE SAMPLE LIBRARY FILES TO CD‑ROM ‑ Burning Down The House

Quick Links To Other S‑Series And W‑Series Pages: Sample Disk Image Reader Synth & Sampler Firmware/Binaries W‑30 Tips & Tricks S‑50 Service Information Sheets Create Your Own W‑30 CD‑ROM's S‑760 Support Info SCSI2SD Example Setups Solve S‑50 Noise & Static Issues S‑50 Support Info Cloning ZIP Disks & Hard Drives SysEx Verification Utility S‑550 Support Info Cloning MicroSD Cards For SCSI2SD Operating System Matrix S‑330 Support Info Roland CD‑ROM Compatibility Matrix Front Panel Display Freakout SP‑700 Support Info RSB Sample Library List Control Inputs/Outputs W‑30 Support Info Toggle Switch For USB Floppy Drive Monitor Cables. RGB & Composite Startup Floppy Disks S‑760 Encoder Replacement Download Vintage CD-ROM's Download Free Samples |

"dd" ‑or‑ OMNIFLOP ‑or‑ SDISKW ???

The built‑in "dd" utility on the Mac is what I use all the time now to create, copy and archive all of my 3.5" floppy disks. It's a quick, no frills solution for creating and sharing floppy disks, *.IMG and *.OUT Disk Image files for the S‑Series, W‑Series and DJ‑Series samplers

Until I discovered the "dd" tility on the Mac, OmniFlop was my favorite utility on my Windows PC for creating S‑Series, W‑Series and DJ‑Series sampler disks from *.OUT files. OmniFlop is an excellent tool for creating and sharing *.IMG and *.OUT Disk Image files for use with a USB Floppy Drive Emulator (USB/FDE). Also, a required utility if you still use floppy disks with your sampler. I highly recommend using OmniFlop as a replacement for the DOS based SDISK and its Windows counterpart SDISKW. OmniFlop even has a special menu selection for working specifically with Roland sampler disks

I initially had some minor hardware issues with installing a working 3.5" floppy disk drive. It turned out that only the old‑style 720KB DS/DD or 720KB/1.44MB Dual Support drives will work. The newer and (of course) less expensive 1.44MB DS/HD will only write disks for use with the S‑750/S‑760/S‑770 samplers. After solving that problem, I compiled some useful installation notes here

SDISKW is a good program to use if you plan to use only 3.5" floppy diskettes with your Roland sampler and don't want to work with any advanced disk image files (*.OUT, *.IMG, *.S50, *.S33, *.W30, etc...). SDISKW might also be a better choice for you since it will work with an external USB FDD. Each of these utilities has an advantage over the other

"dd", OmniFlop, SDISKW and 3.5" Floppy Disk Drive Installation Notes

"dd", OmniFlop, SDISKW and 3.5" Floppy Disk Drive Installation Notes

GOTEK USB Floppy Drive Emulator (USB/FDE)

There are many methods of making a GOTEK USB Floppy Drive Emulator (USB/FDE) work with a Roland S‑50, S‑550, S‑330, S‑7xx or W‑30 sampler. The easiest way is to buy GOTEK Model: SFRM72‑FU‑DL for about $25 (USD) and simply plug it into the sampler where the floppy disk drive used to sit. The disadvantage of using this model is that there are very few bells and whistles available. The GOTEK factory firmware on this model uses a very boring 7‑segment LED display and the two buttons on the front make a clumsy user interface

Luckily, there are alternatives for updating the GOTEK firmware and the best version I've seen is available for free. You can purchase a low‑priced GOTEK for about $17 (USD), a nice, crisp OLED screen for $2, a rotary encoder for $3 and update the firmware yourself using free installation software. In the past, other firmware updates required a special serial interface and a $10 software license for each GOTEK you updated

The only extra hardware you need for this free FlashFloppy firmware update is a standard USB cable. When I updated my GOTEK with the FlashFloppy firmware, installed the OLED and rotary encoder, It worked perfectly the very first time I tried it. Very unusual for mods like this when trying to make 1980's technology work with modern gadgets. In fact, after all the updates went so smoothly, I thought perhaps that something had gone wrong

Keep in mind that the OLED screen and Rotary encoder are optional add‑ons but... for these low cost parts, I highly recommended adding them. It's like the difference between driving a Ford Pinto and a Corvette Stingray

A link to installing a GOTEK USB/FDE on your Roland sampler using the free FlashFloppy firmware is here

(This firmware update requires free software installation and additional parts [optional] which requires soldering)

A link to installing a GOTEK USB/FDE the easy way on your Roland sampler is here

(No soldering or extra modification is required for this method)

There are many methods of making a GOTEK USB Floppy Drive Emulator (USB/FDE) work with a Roland S‑50, S‑550, S‑330, S‑7xx or W‑30 sampler. The easiest way is to buy GOTEK Model: SFRM72‑FU‑DL for about $25 (USD) and simply plug it into the sampler where the floppy disk drive used to sit. The disadvantage of using this model is that there are very few bells and whistles available. The GOTEK factory firmware on this model uses a very boring 7‑segment LED display and the two buttons on the front make a clumsy user interface

Luckily, there are alternatives for updating the GOTEK firmware and the best version I've seen is available for free. You can purchase a low‑priced GOTEK for about $17 (USD), a nice, crisp OLED screen for $2, a rotary encoder for $3 and update the firmware yourself using free installation software. In the past, other firmware updates required a special serial interface and a $10 software license for each GOTEK you updated

The only extra hardware you need for this free FlashFloppy firmware update is a standard USB cable. When I updated my GOTEK with the FlashFloppy firmware, installed the OLED and rotary encoder, It worked perfectly the very first time I tried it. Very unusual for mods like this when trying to make 1980's technology work with modern gadgets. In fact, after all the updates went so smoothly, I thought perhaps that something had gone wrong

Keep in mind that the OLED screen and Rotary encoder are optional add‑ons but... for these low cost parts, I highly recommended adding them. It's like the difference between driving a Ford Pinto and a Corvette Stingray

A link to installing a GOTEK USB/FDE on your Roland sampler using the free FlashFloppy firmware is here

(This firmware update requires free software installation and additional parts [optional] which requires soldering)

A link to installing a GOTEK USB/FDE the easy way on your Roland sampler is here

(No soldering or extra modification is required for this method)

GBS‑8200 CGA/EGA/YUV To VGA Video Converter Board DIY

This is an inexpensive way to connect your S‑50, S‑550, S‑330 or S‑7xx to a standard 15‑pin LCD Flat Screen VGA Color Monitor. This DIY project was much easier than I expected. The results are GREAT and so are the cost savings! Thanks to this tiny video board, I'm now able to use my S‑50, S‑550 and S‑760 samplers with a sharp looking, crisp and clean 17" Dell (15-Pin), Atari (13-Pin), Sharp (17-Pin), Envision (17-Pin), LCD color display. The monitors I used for testing were standard 15‑Pin VGA which were previously used with generic video boards on a PC. I am assuming that just about any 15‑pin LCD Flat Screen VGA Color Monitor will work with this DIY. I also had a cheap leftover +5V DC power supply so my total investment was less than $35 (USD)

This is an inexpensive way to connect your S‑50, S‑550, S‑330 or S‑7xx to a standard 15‑pin LCD Flat Screen VGA Color Monitor. This DIY project was much easier than I expected. The results are GREAT and so are the cost savings! Thanks to this tiny video board, I'm now able to use my S‑50, S‑550 and S‑760 samplers with a sharp looking, crisp and clean 17" Dell (15-Pin), Atari (13-Pin), Sharp (17-Pin), Envision (17-Pin), LCD color display. The monitors I used for testing were standard 15‑Pin VGA which were previously used with generic video boards on a PC. I am assuming that just about any 15‑pin LCD Flat Screen VGA Color Monitor will work with this DIY. I also had a cheap leftover +5V DC power supply so my total investment was less than $35 (USD)

The parts required to make this DIY work are

You can download the GBS-8200 Operation Manual at this link

Build Procedure

1) Take the white 8‑pin connector that came with the GBS‑8200 video board and move the grey wire in Slot "S" over to Slot "HS". To remove the grey wire, use a needle to press down on the metal connector then gently pull the wire up and out (see Figure 1). The reason for moving this wire from Slot "S" over to Slot "HS" is because an HSYNC signal is required for S‑50, S‑550, S‑330 and S‑7xx RGB video output. The grey wire by default on the GB‑8200 video board is connected to an "S" video signal (CSYNC), not HSYNC

2) Solder the six wires on the white 8‑pin connector that came with the GBS‑8200 video board onto the 8‑pin male DIN connector

Because these wires are supplying video signals, I opted to shield them by wrapping three layers of aluminum foil around the entire six wire cable assembly. I then took some black electrical tape and wrapped everything tightly. I'm not sure if the shielding is necessary but I did it just to play it safe

3) Connect all the cables and power on all the devices...

Make sure the power supply you are using is "center tap" positive!)

- 8‑pin male DIN connector, full size (Switchcraft P/N#: 15BL8MX)

- 15‑pin LCD Flat Screen VGA Color Monitor (or any VGA Color Monitor if it uses a 15‑pin VGA connector)

- +5V DC (2A) power supply, center tap positive (See an example at this link)

- GBS‑8200 CGA/EGA/YUV to VGA Video Converter Board v4.0 (I paid $24 (USD) from eBay w/free shipping)

- It is highly recommended to place the GBS‑8200 board inside of a protective metal enclosure to keep it static‑free and safe from any ESD mishaps. A good size is a 1590DD diecast aluminum guitar pedal enclosure. Originally designed by Hammond, high quality generic 1590DD enclosures can be found at Tayda anywhere from $9.99 to $14.99 (USD) depending on color styles. There are some very wild Day‑Glo Orange and Fluorescent Green colors along with boring brushed aluminum models to choose from. The drawback to using a 1590DD enclosure is that they are very difficult to create openings for VGA and power cable access. The aluminum walls are very thick. A hacksaw and drill press are required. See a large selection of inexpensive 1590DD enclosures here

You can download the GBS-8200 Operation Manual at this link

Build Procedure

1) Take the white 8‑pin connector that came with the GBS‑8200 video board and move the grey wire in Slot "S" over to Slot "HS". To remove the grey wire, use a needle to press down on the metal connector then gently pull the wire up and out (see Figure 1). The reason for moving this wire from Slot "S" over to Slot "HS" is because an HSYNC signal is required for S‑50, S‑550, S‑330 and S‑7xx RGB video output. The grey wire by default on the GB‑8200 video board is connected to an "S" video signal (CSYNC), not HSYNC

2) Solder the six wires on the white 8‑pin connector that came with the GBS‑8200 video board onto the 8‑pin male DIN connector

S‑50 / S‑550 8‑PIN DIN MALE PLUG GBS‑8200 VIDEO BOARD 8‑PIN WHITE CONNECTOR (P11) VIDEO SIGNAL PIN# PIN# WIRE COLOR VIDEO SIGNAL GROUND 2 <----------------------> GD BLACK GROUND VSYNC 5 <----------------------> VS YELLOW VSYNC HSYNC 4 <----------------------> HS GREY HSYNC [AFTER MOVING WIRE] BLUE 8 <----------------------> B BLUE BLUE GREEN 7 <----------------------> G GREEN GREEN RED 6 <----------------------> R RED RED +5V 1 DO NOT USE - NO WIRE DO NOT USE OPEN 3 DO NOT USE S NO WIRE DO NOT USE

Because these wires are supplying video signals, I opted to shield them by wrapping three layers of aluminum foil around the entire six wire cable assembly. I then took some black electrical tape and wrapped everything tightly. I'm not sure if the shielding is necessary but I did it just to play it safe

3) Connect all the cables and power on all the devices...

Make sure the power supply you are using is "center tap" positive!)

Another S‑550 owner with this same video board has put together a great overview of how it works including the menus. For more details check out freudelheim

Issue: Screen shaking or rolling around

TROUBLESHOOTING

If you end up getting lost and venture into the cryptic Chinese menus by mistake, the quick route to get English displayed is made by pressing:

MENU > UP > MENU > UP > UP > MENU > MENU

Other menu button functions (with no OSD menu showing on the monitor)

Auto‑Scan: DOWN/AUTO

Reset The Board: Press and hold DOWN/AUTO for 5 seconds

Video Mode‑Select (RGBS / RGBHS / YPbPr): SW (RGBS = 15‑pin VGA connector)

This video board is very easy to use. If you need additional menu info and technical specs, download the GBS-8200 Operation Manual at this link

If this video board will be used with an S‑50 or S‑330, an inexpensive metal housing is recommended to keep the static sensitive components safe. I use a Hammond 1599DD aluminum enclosure (normally used as a guitar pedal case). These protective enclosures are readily available from Tayda Electronics here. If this is to be used with an S‑550 and there is no HD5‑IF SCSI Interface Card installed, you can do what I did and take advantage of the empty space on the underside. Place the video board inside the sampler like so...

$20 (USD). Now that's the kind of DIY I like... nice and inexpensive!

If needed, here is some more detailed info;

I tested the GBS‑8200 video board with a Sharp LL‑T15A4‑B 15" LCD Flat Screen VGA Color Monitor (manufactured in 2003 ‑ specs) and a Dell E176FP 17" LCD Flat Screen VGA Color Monitor (manufactured in 2006 ‑ specs). In addition to a standard 15‑pin VGA Out connector, there is also a 12‑pin socket (P12) on the GBS‑8200 video board which provides a video output signal for R, G, B, VSYNC, HSYNC, and GROUND. If you have an older style monitor like a CGA, EGA, or RGB, this extra 12‑pin connector might be able to adapt to those older style monitors by using a different connector arrangement. For this DIY, the included 8‑pin connector (P11) with six wires was used. You might be tempted to use a tap off of the main S‑550 circuit board to supply power for the GBS‑8200 video board. Don't do it. Ordering a replacement circuit board for vintage gear like the S‑550 is not an option. Play it safe and stick with a cheap external power supply. An external power supply will also help to isolate any hum the GBS‑8200 video board might introduce into the S‑550 audio circuit

Old RGB Monitors

Some of the older RGB color monitors that work with the Roland S‑50, S‑330, S‑550, S‑750, S‑760 and S‑770 use an oddball 8‑pin rectangular female connector (the official name for this connector is "SMK EIAJ 8‑Pin Female VTR Connector"). The color monitors distributed by Roland were P/N#: CC‑121 and P/N#: CC‑141. Similar RGB monitors were Amdek Color-II, Taxan RGB Vision-I, II & III and Sony Trinitron KV-1311CR. The cable needed for use with these old monitors is very difficult to find. Roland manufactured this cable with a rectangular male connector as P/N#: RGB‑25N

If you want to build your own cable, the cost to get all the parts (not including shipping) is about $40 (USD)

RGB‑25N DIY Cable Parts, Vendor Links, Instructions & Wiring Diagrams

RGB‑25N DIY Cable Parts, Vendor Links, Instructions & Wiring Diagrams

Partial List Of Monitors With An 8-Pin Digital RGB Input Connector

Partial List Of Monitors With An 8-Pin Digital RGB Input Connector

Two popular RGB monitors of days gone by were the Atari SC1224 and SC1435. These monitors used a strange 13‑pin connector. If you want to build your own cable, the cost to get all the parts (not including shipping) is about $35 (USD)

Atari SC1224 And SC1435 DIY Adapter Cable Parts, Instructions & Wiring Diagrams

Atari SC1224 And SC1435 DIY Adapter Cable Parts, Instructions & Wiring Diagrams

How To Share 1 Monitor With 2 Or More Roland S‑Series Samplers

If you have 2 or more Roland S‑Series Samplers, this inexpensive DIY is for you. Complete plans are contained in this PDF file

S-50_S-550_A-B_Switch-Box_DIY

S-50_S-550_A-B_Switch-Box_DIY

Using A Non‑Roland Mouse With The S‑550, S‑330 And S‑7xx Samplers

NOTE: The S‑50 will not work with any type of mouse. The EXT CONTROLLER port on the back of the S‑50 will only work with the optional DT‑100 Digitizer Tablet. If you plug a mouse into the EXT CONTROLLER port, you run the risk of causing a short circuit in the sampler. Likewise, if you plug a non‑Roland mouse into the EXT CTRL port on the S‑550, S‑330, S‑750, S‑760 or S‑770, you run the risk of causing a short circuit. If this happens, see info about replacing the PICO® fuse at the section on this webpage called Mouse Or RC‑100 Is Unresponsive, Intermittent Or Not Working

After losing bid after bid on expensive MU‑1 and MSX mice at eBay, I decided to purchase a KMTech PS/2 to MSX mouse adapter instead. It works flawlessly with my S‑550 and S‑760. The adapter is very small at 63mm x 19mm x 13mm. Compared to the price of a used MSX mouse, this clever adapter board is a bargain at $31 (USD) + shipping. The overseas shipping to the USA was amazingly fast at only 6 business days! The seller is kevinmount* who has a 100% Feedback Rating on eBay

* The item was PS/2 to MSX Mouse Adapter and was purchased from kevinmount

Ship time: 6 days from United Kingdom to the USA

The big advantage this adapter has over an MU‑1 mouse is that if the PS/2 mouse goes bad, a replacement is inexpensive as opposed to finding another expensive MU‑1 mouse on eBay. Plus, every MU‑1 or MSX mouse I've seen for sale on eBay is being sold as a used item and is already 30+ years old. I've had excellent results using a WYSE PS/2 (P/N: 770510‑21L / LED Optical Type) and a DELL (P/N: M-S34-6MD / Ball Wheel Type). It's recomended that when using a LED Optical Type mouse, do not use a mousepad with complex patterns. Use one with a solid color or the mouse pointer will jump around the screen

My only complaint about the board is that it needs some type of a cover. My solution was to wrap everything with black electrical tape. I can't stand to have an exposed circuit board with static sensitive components glaring at me. It goes against everything I was taught about electronics

2‑Prong Power Cable Replacement DIY

Tired of always looking for that oddball 2‑Prong AC power cable? Do something about it. Here's a super simple mod that will let you use the more common 3‑prong AC cable with your Roland sampler. The cost for parts was less than $1. In addition to always being able to find the right AC cable, this mod adds ground circuit protection. Why is that important? Just ask several S‑50, S‑550, W‑30 and SP‑700 owners who connected their sampler to an ungrounded mixing board. The audio output transistors on their samplers were toasted to a crisp!!!

The mod is so simple that all it needs is a picture to explain. It's easy as 'connect the dots'. If you buy the correct sized AC power adapter (P/N: 703W‑00/03), it's a 1 for 1 swap, no case modification and no sheet metal to cut. There's even a pre‑drilled hole in the case for the ground wire. Just piggy‑back onto one of the screw holes used for the serial number plate. Easy! The DIY image shows the mod for an MKS‑70 but this will also work with an S‑50, S‑550, W‑30, MKS‑50 and a bunch of other Roland rackmounts and keyboards. If you are using a sampler with something running other than 110/117V AC, please note... this mod has NOT been verified to work on a sampler running 220V/240V. This mod is only for those with electronics experience. Author accepts no liability if you damage your synth or hurt yourself. Always keep one hand behind your back when working with live electrical circuits. It's the best way to stay alive

S‑50, S‑550 And W‑30 AC Power Receptacle Replacement DIY

S‑50, S‑550 And W‑30 AC Power Receptacle Replacement DIY

SP‑700 AC Power Receptacle Replacement DIY

SP‑700 AC Power Receptacle Replacement DIY

If you just want to buy a 2‑prong AC replacement cable for your S‑50, S‑550 or W‑30, don't pay the ridiculous high prices at eBay or elsewhere

The 2‑prong replacement cable is Hosa P/N: PWC-178 and is available at sweetwater.com + always FREE Shipping / NO Minimum!

W‑30 LCD Replacement DIY

Detailed instructions for replacing your old LCD. Not the easiest DIY in the world but the good news is for under $30 (USD), you can get rid of that annoying high pitched shrill in the process

* * * Update: December 2021 * * * A new version of this DIY manual is now available. Feedback from others report that a 100 Ω / 1W resistor works best with the Blue, Black and Monkey Vomit Green displays. Also, most people agree that cutting off the existing LCD wiring harness and reusing it is easier than assembling a new Hirose connector so this has been added as Option #1

W‑30 Backlight Replacement

Over time, the W‑30 backlight will begin to fail and get dimmer. It takes a while to disassemble the W‑30 to gain access to the LCD, but installing a new Electroluminescent Panel (ELP) segment is quick and easy. The old ELP slides out easily after unsoldering two leads

There are several vendors on eBay selling ELP's the price range of $8 to $20 (USD). The most common colors available are Blue or White

When soldering in place, use a heatsink (a large coin also works well) and touch the leads with the soldering iron for only very brief moments and use a lower than normal temperature for the soldering iron. I had to trim off about 1mm from the top and bottom edges to make it fit. However, it's not an issue because this flexible ELP may be bent or cut into any shape. This ELP also works with Roland S‑750, S‑770, AKAI, Kurzweil and EMU samplers. The Roland W‑30 Blogspot has some good before/after pictures about this replacement. A green ELP is shown on that webpage but the instructions are valid

* * * Please Note * * * If your W‑30 has a high pitched and incredibly annoying shrill, that sound is caused by a failing high voltage inverter circuit which drives this ELP. Replacing the ELP will not stop this annoying sound. Your best course of action would be to replace the entire LCD assembly as detailed at this link

One of the most common failures on the W‑30 is a broken LCD Contrast Potentiometer which is located on the back of the sampler. This knob has a tendency to break easily during transport because Roland used a sub‑standard plastic part. Symptoms are a wobbly, unreliable knob or worst case scenario, a blank LCD. You can replace this one using an Alpha brand 9mm B10KΩ potentiometer. The cost is only 67¢ (USD) and is available from taydaelectronics.com. The part number is SKU: A‑1850

This part is not a direct "drop‑in" replacement. Replacing this one is a little tricky because of the tight quarters and the case alignment. I had to cut off a small section at the end of all three pins and bend them at a right angle to make it fit into the PCB holes. I cut two 25mm sections from a strong paperclip, sanded off the outer chrome and soldered them to the ground frame of the pot. I then soldered the other ends to the empty GROUND trace holes on the PCB for stability (the empty GROUND trace holes were leftover from the old potentiometer). The result was a perfect fit. The old potentiometer I removed was a B5KΩ so I'm not sure if the previous owner of this sampler replaced it sometime in the past or if Roland changed the value to a B5KΩ on later production models?!? The schematics in the W‑30 Service Notes say this part should be a B10KΩ pot so that's what I used

Don't get your potentiometers locations mixed‑up like I did

Note: This replacement part from taydaelectronics.com is also a plastic part just like the Roland original. A metal shaft potentiometer is too large to fit through the opening in the case unless you drill it larger. You can take your replacement one step further and cut the plastic shaft off flush with the back of the case and add a flat‑blade screwdriver notch for adjustment. This way, if the back of the sampler gets knocked around during transport, the recessed knob will be unaffected. The drawback is of course, it's not very easy to adjust the contrast knob while you are on stage

The INPUT GAIN Potentiometer is also a part which breaks easily but this potentiometer is much harder to replace because of it's odd‑ball value which is C5KΩ (Anti‑Logarithmic). To date, I've been unable to source an equivalent part number for this potentiometer

S‑50 And W‑30 Control Jack Templates

I designed these templates after being frustrated time and time again by having to move my S‑50 and W‑30 away from the wall to locate where certain audio and control jacks are located. This makes it easier to plug cables in and out without having to always face the back of the sampler... or use a mirror. There are four template variations with different fonts and color schemes for each sampler

S‑50 Control Jack Templates

S‑50 Control Jack Templates

W‑30 Control Jack Templates

W‑30 Control Jack Templates

File Format: PDF Document

Mouse Or RC‑100 Is Unresponsive, Intermittent Or Not Working (S‑550, S‑330, S‑750 & S‑770)

I always thought the mouse interface on the S‑550 sucked due to a poorly designed operating system. It turns out those claims were unwarranted. I didn't know it at the time but the problem was always with the EXT CTRL 9‑pin connector on the front panel. I opened up five S‑550's and all five had broken or loose solder connections at this PCB location. Due to age, excessive pressure on the case, strain on the 9‑pin connector or a combination of all three, these solder connections break off or become loose. Some of the symptoms include

If you are still having problems with the mouse or RC‑100 after extensive troubleshooting, be aware that there is a 1/6W PICO® fuse resistor which may have blown. I remember back in the 1980's when a rash of Atari computers had a similar problem. If a device other than an Atari mouse or joystick was plugged into the 9‑pin jack, it would sometimes create a short and blow a PICO fuse because one of the pins carries a +5V signal. A similar situation may exist here with the S‑550, S‑330, S‑750 and S‑770 (Note: The S‑760 does not use a PICO fuse in the EXT CTRL circuit)

Miscellaneous Fuses

This Fast Blow PICO Fuse (P/N: 0251.750NAT1L) manufactured by Littelfuse has nearly the same resistance as the original of 150mΩ. This one (P/N: 0251.630MXL) will also work in a pinch. It has a lower blow point (630mA vs. 750mA) and a higher resistance (200mΩ vs. 150mΩ). The differences are so minimal that it should not be an issue (i.e. only 50mΩ so... as long as the blow point is lower and the resistance is somewhat close, you're covered

▶ SPECIAL NOTE: If you replace the PICO fuse, take extra care to observe how Roland installed it! This fuse sits far above the PCB and away from other components, about 25mm. This is on purpose so that if this fuse does blow, it won't scorch other nearby components or traces on the PCB from the excess heat it generates during failure. Since this is a "Fast Blow" fuse, use a heatsink when soldering it in place. Use a slightly lower than normal soldering temperature (less than 350℃ / 662℉) and don't let the soldering iron make contact for more than five seconds at a time. Otherwise, the performance may be deteriorated or the fuse may open

RGB Video Output Not Working (S‑550, S‑330, S‑750, S‑760 & S‑770)

If your sampler is having an issue with no video output, it is possible that a fuse in the video circuit has blown. Just like the mouse circuit, the same 1/6 Watt PICO® Fuse Resistor is used. This Fast Blow PICO Fuse (P/N: 0251.750NAT1L) manufactured by Littelfuse has nearly the same resistance as the original of 150mΩ. This one (P/N: 0251.630MXL) will also work in a pinch. It has a lower blow point (630mA vs. 750mA) and a higher resistance (200mΩ vs. 150mΩ). The differences are so minimal that it should not be an issue (i.e. only 50mΩ so... as long as the blow point is lower and the resistance is somewhat close, you're covered

▶ SPECIAL NOTE: If you replace the PICO fuse, take extra care to observe how Roland installed it! This fuse sits far above the PCB and away from other components, about 25mm. This is on purpose so that if this fuse does blow, it won't scorch other nearby components or traces on the PCB from the excess heat it generates during failure. Since this is a "Fast Blow" fuse, use a heatsink when soldering it in place. Use a slightly lower than normal soldering temperature (less than 300℃ / 572℉) and don't let the soldering iron make contact for more than three seconds at a time. Otherwise, the performance may be deteriorated or the fuse may open

▶ SPECIAL NOTE: If you replace the PICO fuse, take extra care to observe how Roland installed it! This fuse sits far above the PCB and away from other components, about 25mm. This is on purpose so that if this fuse does blow, it won't scorch other nearby components or traces on the PCB from the excess heat it generates during failure. Since this is a "Fast Blow" fuse, use a heatsink when soldering it in place. Use a slightly lower than normal soldering temperature (less than 300℃ / 572℉) and don't let the soldering iron make contact for more than three seconds at a time. Otherwise, the performance may be deteriorated or the fuse may open

One important thing to know is that Pin #1 of the 8-pin DIN connector in the video circuit is connected to the PICO fuse and +5V DC. Pin #1 is used by some monitors and some external video boards but not by others. SCART external video boards and some older RGB monitors require a connection to Pin #1. The GBS‑8200 external video board and some older RGB monitors like the Atari SC1224 and SC1435 do not use a Pin #1 connection. If you have no video output with the latter, replacing the PICO fuse will not help so look elsewhere for the problem. If you have no video out and are using an external SCART video board, check for a fried PICO fuse

No Sound Output Or Scratchy Sound Output/Input (S‑550, S‑220 & MKS‑100)

Broken traces on the Switch Board are a common point of failure with the S‑550, S‑220 & MKS‑100. Over time, moving the sampler around will place too much strain on a particular section of the Switch Board and it will eventually crack. This usually occurs when the module is shipped from Point A to Point B. Broken traces on the board will set the total output volume knob to zero which renders the sampler useless. The problem area is located near the REC LEVEL and VOLUME potentiometers (VR1 and VR2). I was able to fix my S‑550 by using epoxy on the broken PCB then soldered some jumper wires to reconnect the traces which were snapped

Scratchy sound or no sound at all can also be related to the REC LEVEL or VOLUME potentiometers (VR1 and VR2). If you are experiencing scratchy sounds when using either of these potentiometers, you can replace them using an inexpensive one manufactured by Bourns. Just like the original potentiometers, this replacement part has a very short Flatted/D shaft. The pins need to be bent slightly to fit into the PCB holes but it works perfectly

S‑550

VR1 and VR2 are both 10K potentiometers with a Linear Taper - Mouser P/N#: 652-PTV09A-4015FB103

S‑220

VR1 and VR2 are both 10K potentiometers with an Audio Taper - Mouser P/N#: 652-PTV09A-4015FA103

MKS‑100

VR1 is a 50K potentiometer with an Audio Taper - Mouser P/N#: 652-PTV09A4015FA503

VR2 is a 10K potentiometer with an Audio Taper - Mouser P/N#: 652-PTV09A-4015FA103

Distorted Sound Output (S‑550)

If your S‑550 is experiencing distorted sound output, it's possible the previous owner was careless and connected one or more of the 1/4" output jacks to a non‑grounded mixer or some other type of non‑grounded equipment. Since the S‑550 is not grounded by default, this can easily damage one or more of the nine output transistors on the Analog Board (this board is located in the compartment underneath the sampler). It's an easy fix if you are handy with a soldering iron. Replace all nine 2SC2878A transistors at locations Q1 through Q9. As of January 2022, there are a few vendors on eBay and AliExpress selling replacement 2SC2878A transistors. Even if you've isolated only one or two outputs as the culprit, take some extra time and replace all nine transistors while you have the board out. It's possible that other transistors were damaged and are ready to fail soon. Detailed information about this fix is available in this thread over at gearsz.com. This is another reason why it's a good idea to ditch that stupid 2‑prong Roland power cable and add a three‑prong AC power outlet to your Roland samplers/synths to ensure proper grounding! If you are in a jam and can only find 2SC2878-B transistors, they will work but... you will need a transistor tester to measure and select only those with an hFE less than 700

S‑50 Noise, Static And Distortion Issues

If your S‑50 is experiencing noise, static or distorted audio then join the crowd. Over time, the S‑50 can start to experience a problem with the relay coil which is located on the Jack Board. The relay coil is there to temporarily delay an inrush of current to the Audio Out circuit so that any annoying loud pops are avoided when you power on the sampler. The Audio Out circuit is essentially turned off for a couple of milliseconds

The three solutions I know of are to Replace It, Clean It or Bypass It

SOLUTION #1 - Replacing The Coil

Tom Arnold, another S‑50 owner, has supplied an excellent solution which has been verified by several online visitors here. He designed a very small PCB which is used to replace the single relay coil by using three inexpensive, low current and easy to source relays. The big advantage to this solution is these new relays are easily swapped out when they fail. According to Arnold, the S‑50 design is prone to failure because the original single relay coil and replacement relays will eventually fail over time. Since it's very difficult to remove and clean the factory installed relay coil, swapping out three 0.85¢ relay coils makes more sense because they are socketed on this new PCB

"This is a 3DPDT relay board to replace the 6PDT relay in the Roland S‑50. Two holes in the middle are for hold‑down screws. I recommend putting in sockets so you can replace the relays more easily as they will go out again the way they are being used."

The best price I've seen for these new relays is only 0.85¢ each from Allied Electronics. You'll need to buy three 16‑pin IC sockets and three 5V relays (Zettler P/N#: AZ822‑2C‑5DSE)

The bad news is that OSHPark has a minimum purchase of three PCB's. The good news is they only cost $3/each

PCB's designed by Tom Arnold are available from OSHPark here

PCB's designed by Tom Arnold are available from OSHPark here

5V Relays From Allied Electronics - here

5V Relays From Allied Electronics - here

UPDATE (November 2018) : Open Mirror from Australia was able to install this new PCB and Relay setup into his S‑50 before I was able to (it's still on my To‑Do list). He reports excellent results. The distortion he was experiencing has completely disappeared

Click here for images of his installation plus... Before & After sound comparisons

Click here for images of his installation plus... Before & After sound comparisons

SOLUTION #2 - Cleaning The Coil

Jim Atwood Of Japan has a step‑by‑step solution for cleaning the relay coil at this link;

S‑50 Noise, Static And Distortion Solution

S‑50 Noise, Static And Distortion Solution

SOLUTION #3 - Bypass The Coil

Some online visitors have reported they have bypassed the coil completely and just remember to keep the volume slider at zero when powering up. Since this will significantly alter the original circuit design, I won't provide any info about that fix. It seems risky, IMO

The S-50 Or S-550 Front Display Panel Is Blank / Freaking Out / Intermittent

Q: I have an S‑50 / S‑550 and the display screen is blank or acts weird. What can I do?

A: Some owners have reported failures with bad solder connections on the FIP display. Use a magnifying glass to inspect for hairline cracks and reflow NEW solder if needed. The FIP driver coil for the display panel is also a common point of failure with the S‑50, S‑550, Super JX‑10, MKS‑70 and other Roland synths. The cause is a manufacturing defect which has been traced to the Sumida Corporation, the only supplier of this coil (P/N: 12449251). Unfortunately, sources for replacement coils are very difficult to find. A supplier on eBay has some redesigned replacements which sell for $75 USD. Another hope is to find an old coil from a cannibalized Roland product which uses the same part number. The JX‑10, JX‑8P, GM‑70, GR‑1, DDR‑30, S‑50 and S‑550 synths/samplers all use the same part number. However, be aware that these coils may also be defective. There seems to be no rhyme or reason as to when or if a coil will fail. Guy Wilkinson has a webpage with detailed troubleshooting of the FIP display and FIP coil at this link

Note: The image on the right shows the coil on an S‑550 Main Board as denoted by the silkscreen label T1. The coil for an S‑50 is located on the Panel Board Assembly and has a silkscreen designation of L1 even though these are the same part number. Also, the MKS‑70 synth uses a nearly identical coil but the windings are slightly different. The coil from an MKS‑70 will most likely work in a pinch

Tact Switch Replacements

The Operating Life for tact switches is realistically, probably 10 years until stress and/or oxidation starts to set in and they become intermittent. Removing old tact switches from the PCB is a matter of personal preference. The method I prefer is to use a small sharp pair of diagonal flush wire cutters and cut all four leads off from the top side of the PCB. Take extra care not to wedge the wire cutters in‑between the base of the tact switch and the PCB when cutting the leads. This places excess force on the via traces on the underside of the PCB causing possible damage. Use a solder sucker, a fine tipped soldering iron or a stainless steel hollow desoldering needle and remove the leftover pins from the PCB holes. Remove any excess solder remaining in the holes. The vias on the brittle 30+ year‑old PCB's are very fragile. Take extra care not to lift them off the surface of the PCB while desoldering. Using too much heat or keeping the soldering iron too long in one spot usually leads to this type of problem

The Operating Life for tact switches is realistically, probably 10 years until stress and/or oxidation starts to set in and they become intermittent. Removing old tact switches from the PCB is a matter of personal preference. The method I prefer is to use a small sharp pair of diagonal flush wire cutters and cut all four leads off from the top side of the PCB. Take extra care not to wedge the wire cutters in‑between the base of the tact switch and the PCB when cutting the leads. This places excess force on the via traces on the underside of the PCB causing possible damage. Use a solder sucker, a fine tipped soldering iron or a stainless steel hollow desoldering needle and remove the leftover pins from the PCB holes. Remove any excess solder remaining in the holes. The vias on the brittle 30+ year‑old PCB's are very fragile. Take extra care not to lift them off the surface of the PCB while desoldering. Using too much heat or keeping the soldering iron too long in one spot usually leads to this type of problem

After time, some of the buttons (tact switches) will start to act intermittently or fail. The best solution is to replace all of the tact switches at the same time because if you only replace a few, others are bound to fail soon after. eBay and other vendors sell complete sets of tact switches and these range anywhere from $30 (USD) to $92 (USD). Ouch! You can save a lot of money buying them instead from an electronics supplier such as mouser.com. You can get a complete tact switch replacement set from Mouser for less money. Also, ALWAYS buy a few extras because... shit happens!

I try to list two types of replacement tact switches to choose from. Why? I prefer a harder press Operating Force of 2.6 Newton because I like to hear that solid 'Click!' whenever I make a selection

(S‑50 / S‑750 / S‑770 / W‑30 Tact Switches)

1) Brand Name: ALPS

Manufacturer P/N: SKHHAMA010

Mouser P/N: 688-SKHHAM

Operating Force: 1.6 Newton (Black)

Operating Life: 500,000 cycles

Size: 5mm (H) x 6mm (W) x 6mm (D)

[ Alternate P/N: OMRON B3W-1000S ]

2) Brand Name: ALPS

Manufacturer P/N: SKHHARA010

Mouser P/N: 688-SKHHAR

Operating Force: 2.6 Newton (Red)

Operating Life: 200,000 cycles

Size: 5mm (H) x 6mm (W) x 6mm (D)

[ Alternate P/N: OMRON B3W-1002S ]

I do not own an S‑750 or S‑770 so the P/N's for these two samplers are speculative and I'm relying on feedback from other owners

(S‑550 Tact Switches)

Three different types of tact switches for the S‑550 are distributed all over the place!

There are 14 used for the Command Keypad, 13 for the Alphnumeric Keypad and 1 inside the case on the Main PCB

Three different types of tact switches for the S‑550 are distributed all over the place!

There are 14 used for the Command Keypad, 13 for the Alphnumeric Keypad and 1 inside the case on the Main PCB

Command Keypad (SW2 through SW15 - Quan: 14)

Brand Name: ALPS

Manufacturer P/N: SKHHBSA010

Mouser P/N: 688-SKHHBS

Operating Force: 2.6 Newton (Red)

Operating Life: 200,000 cycles

Size: 9.5mm (H) x 6mm (W) x 6mm (D)

Alphanumeric Keypad (SW16 through SW28 - Quan: 13)

Brand Name: ALPS

Manufacturer P/N: SKHHARA010

Mouser P/N: 688-SKHHAR

Operating Force: 2.6 Newton (Red)

Operating Life: 200,000 cycles

Size: 5mm (H) x 6mm (W) x 6mm (D)

[ Alternate P/N: OMRON B3W-1002S ]

Main Board PCB (SW1 - Quan: 1)

File this under the category, "If it ain't broke... don't fix it!". This switch is located inside the case on the Main Board PCB and is rarely or never used. It is a reset switch only used for testing purposes. It most likely will never need replacing. The original ALPS part number is no longer available but the dimensions and functionality are identical to ALPS SKHHARA010 shown above. If you must replace this switch, use Mouser PN: 688‑SKHHAR

Brand Name: ALPS

Manufacturer P/N: SKHHAD039A

Operating Force: 1.6 Newton (Dark Gray)

Operating Life: 500,000 cycles

Size: 5mm (H) x 6mm (W) x 6mm (D)

(S‑760 Tact Switches)

Tact switch leads for the S‑760 are mounted extremely close on top of the Panel Assembly PCB and using diagonal flush wire cutters to remove them (as explained above) is not the best method for this sampler. I recommend using the combination of an Exacto razor knife and a stainless steel hollow desoldering needle (or a solder sucker) to remove these small tact switches from the PCB. Heat the solder trace on the backside of the PCB and use the Exacto razor knife to gently pry the tact switch up and out of the PCB via. Use a stainless steel hollow desoldering needle (or a solder sucker) to remove any excess solder from the PCB vias. I found working with the S‑760 Panel Board Assembly to be a real challenge. After soldering the switches in place, two of them did not work because the solder did not make a good connection. I suspect that using a very low temperature setting was the culprit. After reflowing solder on these areas, a good contact was made. I used a very low temperature setting because the 30+ year‑old Roland PCB's and traces are quite brittle and fall apart easily. Also note that the Panel Board Assembly and Encoder Assembly are incorrectly labeled in the S‑760 Service Notes

The total number of tact switches needed for the S‑760 is 13. Do yourself a favor and buy a couple of spares because... shit happens

There are two types of tact switches to choose from. The original Panasonic tact switches installed by Roland had a light touch Operating Force of 1.3 Newton*

1) Brand Name: OMRON

Manufacturer P/N: B3F-6022

Mouser P/N: 653-B3F-60223

Operating Force: 1.5 Newton

Operating Life: 300,000 cycles

Size: 5mm (H) x 6mm (W) x 6mm (D)

2) Brand Name: OMRON

Manufacturer P/N: B3F-6020

Mouser P/N: 653-B3F-60203

Operating Force: 1.0 Newton

Operating Life: 1,000,000 cycles

Size: 5mm (H) x 6mm (W) x 6mm (D)

Note: These switches will also work for the Roland JV‑80, JV‑90, JV‑880, JV‑1080, JV‑2080, U‑20 and XP-50

The original switches I previously recommended were manufactured by Panasonic but these have been discontinued. You may still be able to find some of these from other electronic supply houses like AliExpress

Manufacturer P/N: EVQ-21405R* (This part was marked as obsolete at mouser.com in August 2019)

Manufacturer P/N: EVQ-22705R (This part was marked as obsolete at mouser.com in August 2019)

Tact Switch Reference Page For Other Roland Synths/Samplers

Tact Switch Reference Page For Other Roland Synths/Samplers

S‑760 Rotary Encoder Replacement

Although it's not exactly a "Drop-In" solution, this rotary encoder replacement works extremely well. It requires an inexpensive custom PCB, a low‑cost commonly found rotary encoder and little bit of soldering. I have also supplied an alternate method which does not require a PCB. It takes a little more work but if you are miserly to the extreme... that's the one for you

S-760 Encoder Replacement DIY

S-760 Encoder Replacement DIY

SP-700 LCD Replacement

SP-700 LCD Replacement DIY - Ver. 20220928

SP-700 LCD Replacement DIY - Ver. 20220928

Update May 2025:

SP-700 Wave Memory Upgrade (SIMM's)

SPECIAL NOTE: Use the highest quality memory possible

Otherwise you will experience data corruption ("crackling")

To increase the SP‑700 Sample Wave Memory, use 4MB SIMM's installed in pairs. The maximum memory allowed is 32MB so to reach this level you will need a total of eight 4MB SIMM's. The SIMM's must be 30‑pin, non‑parity and the speed must be 100ns or faster. These are the same style SIMM's used on the S‑750 sampler. Be aware that they are NOT the same style SIMM's used on the S‑760 or S‑770 samplers. The S‑760 SIMM's have 72‑pins and the S‑770 SIMM's are only 1MB. I've been able to find brand‑new 30‑pin SIMM's very cheap on eBay, reverb.com and elsewhere. When searching, look for high quality Macintosh compatible non‑parity SIMM's. Increasing the memory is a breeze because of the easy‑access lid on top of the case. Remove two screws and you're ready to go. See Appendix Pages 2 through 5 of the SP‑700 Owner's Manual for detailed info

After‑Market Floppy Disk Drives

DIY info for replacing an unreliable or broken FDD using inexpensive Chinon, Teac, Panasonic, Mitsubishi, NEC & other brands. Some of the instructions are easy as moving/adding jumpers while others require a steady hand w/intermediate soldering skills

FDD Tech

FDD Tech

S‑550 3.5" FDD Warning

Take special care when working with FDD's on the S-550. Why? All of the S‑550 ribbon cables I've ever seen were installed backwards at the factory. Never trust the keyed notch, arrow or stripe on the S‑550's 34‑Pin ribbon cable connector. Ensure that Pin‑1 on the ribbon cable matches up with Pin‑1 on the disk drive. Pin‑1 is usually silk‑screened on the FDD PCB somewhere and also on the S‑550 Main PCB. Click on Figure 1 for a larger image which shows this problem in detail

ZuluSCSI

ZULUSCSI FOR THE S-760 AND SP-700

If you want to add SCSI to your S‑760 or SP‑700, the new ZuluSCSI is the best and least expensive option these days. It's simple to use and 100x easier to setup than the old SCSI2SD, raSCSI, piSCSI and BlueSCSI cards. I was amazed at how fast I was up and running. I copied some *.iso and *.img files onto an SD card and was immediately loading and saving samples

The DIY crowd will be happy to know there is a ZuluSCSI board for only $69 which includes 99.9% of the components pre‑soldered in place (ZuluSCSI RP2040). Just add the optional DB25F connector yourself to save big $$$ from Rabbit Hole Computing. If you buy this kit you will need the extra DB25F connector for the S‑760, SP‑700 (and S‑550, W‑30, DJ‑70MKII) so be sure to add it to your cart before checking out. If you are not much of of a DIY person then you're still covered. Anyone with basic soldering skills can easily solder the DB25F connector in place. The SCSI bus on the S‑760 and SP‑700 supplies it's own +5V DC power so there is no need to use an external power supply with the ZuluSCSI RP2040. It is important to note that the ZuluSCSI Compact RP2040 Homebrew Kit, ZuluSCSI Compact RP2040 and ZuluSCSI Laptop models do not have the option to add a DB25F connector. Also, the ZuluSCSI Mini RP2040 does have a DB25F connector installed but... this model requires external +5V DC power for use with the S‑760, SP‑700 (and S‑550, W‑30). This is why I always recommend the ZuluSCSI RP2040 over the other models. It's the most versatile board and I'm able to use it back and forth between my S‑760, SP‑700, S‑550 and W‑30 samplers

If you have any doubts about which board to get for your S‑760, SP‑700 or any other sampler, tech support at Rabbit Hole Computing answers their eMails promptly. Setup instructions and a User Manual can be found at zuluscsi.com

Important: Circuitry inside the S‑760 and SP‑700 samplers have +5V DC present on the SCSI bus line. ZuluSCSI does not require an external power supply when connected to these two samplers when using the ZuluSCSI RP2040 model. Unfortunately, the SCSI bus line on S‑750 and S‑770 samplers does not supply it's own +5V DC power so ZuluSCSI will require an external power supply. If you plan to use a ZuluSCSI board with the SP‑700 sampler, you will need to ensure that the switch labeled TERM POWER (located on the Main Board inside the SP‑700) is set to the ON position (see image to the right). This supplies a line on the SCSI bus with +5VDC which in turn will provide the required power on Pin #25. This switch is easily accessible without having to remove the entire case and is located directly beneath the SIMM memory access lid

ZULUSCSI FOR THE S-550, W-30 AND DJ-70MKII

Please read the info above for the S‑760 and SP‑700 because almost everything applies (i.e. I recommend purchasing the ZuluSCSI RP2040 model and adding the extra DB25F connector). For S‑550, W‑30 and DJ‑70MKII samplers, ZuluSCSI works fine with 80MB hard drives but does not work with CD‑ROM *.iso files (at least I certainly can't make it work. Still trying). The caveat about working with 80MB hard drives is I see no way to create an 80MB hard drive from scratch on the S‑550, W‑30 or DJ‑70MKII. The easiest way is to download this file which contains seven pre‑formatted 80MB blank hard drives (pre‑formatted using the CD‑5 CD‑ROM Utility Disk v1.00). Use one or use many. Your choice. Another workaround is to find an existing 80MB S‑550, W‑30 or DJ‑70MKII *.img file, rename it to HD1.img or HD2.img, etc... and pop it on an SD card. After that, the S‑550, W‑30 or DJ‑70MKII will recognize it and you can use it as‑is with the existing tones contained within ‑or‑ format it and use it as new storage space. For testing, I used the downloads near the bottom of the SAMPLES page named "80MB_Disk-(n).zip"

Another easy way to create blank 80MB files is a built‑in function of the ZuluSCSI firmware. I've not tested this feature yet but others have reported success. From the ZuluSCSI firmware webpage:

Important: The SCSI bus line on S‑550, W‑30 and DJ‑70MKII samplers does not supply it's own +5V DC power. ZuluSCSI will require an external power supply for these three samplers. Also, the S‑550 requires the HD5‑IF SCSI BOARD and the W‑30 requires the KW‑30 SCSI UPGRADE KIT

I mounted my ZuluSCSI RP2040 board inside a 1599XX Metal Stompbox and added a 3-Pin Male Connector,

a 3-Pin Female Connector, three 3.96 Crimp Terminals and a Female Barrel Power Connector for +5V DC operation

This way I'm able to use it externally with the S-550, W-30, S-760 and SP-700 sampler

SCSI2SD

Note: The SCSI2SD project is somewhat outdated these days due to lack of hardware availability

SCSI2HD information previously available on this page has been moved to a separate page at this link

SCSI Hard Drives, CD-ROM's, ZIP Drives And Other SCSI Projects

Note: SCSI Hard Drive, Zip Drive, KW-30 and other SCSI projects previously available on this page have been moved to this link

W‑30 Jog Wheel And Encoder Replacement

Several quality options for replacing your jog wheels and/or encoders

W‑30 Jog Wheel & Encoder DIY

W‑30 Jog Wheel & Encoder DIY

Real‑Time Filter Control For Your W‑30

A very cool, easy and inexpensive DIY using a minimal amount of parts. These same functions can be performed using the Roland EV‑5 or EV‑7 Expression Pedal

W‑30 Real‑Time Filter Control DIY Video

W‑30 Real‑Time Filter Control DIY Video

(This Links To A YouTube Video)

W‑30 Filter Control Sample Files (W-30_Techno_Sounds.zip)

W‑30 Filter Control Sample Files (W-30_Techno_Sounds.zip)

The creator of this very cool DIY sent me some custom W‑30 samples which really take advantage of the different filter controls

S‑550 And W‑30 Firmware: EPROM's or OTP EPROM's?

It is unknown what the final firmware versions are for these two samplers but I suspect they are v2.02 (S‑550) and v1.03 (W‑30)

S‑550

The S‑550 has a pair of EPROM's on the Main Board labeled IC#3 and IC#6 which contain the sampler firmware. Depending on the production year, these IC's are either EPROM's with Quartz windows or One‑Time Programmable EPROM's (OTP). The easiest way to tell is:

On late production models, it will be extremely difficult to upgrade because they will be soldered onto the PCB. The part numbers shown on both of my OTP EPROM's are LH57F003 (v2.00) and other owners have reported LH57F007 (v2.01). This is a Roland manufactured version of the Sharp LH57128‑20 OTP EPROM. It can be read and backed‑up using an EPROM burner but obviously, it will be next to impossible to unsolder it safely from the Main Board without taking a chance on breaking fragile PCB traces. My advice would be to just keep things as they are if you have v2.00, v2.01 or v2.02. I have seen a few rare cases on late production models which have socketed Quartz window EPROM's containing v2.02 firmware

On late production models, it will be extremely difficult to upgrade because they will be soldered onto the PCB. The part numbers shown on both of my OTP EPROM's are LH57F003 (v2.00) and other owners have reported LH57F007 (v2.01). This is a Roland manufactured version of the Sharp LH57128‑20 OTP EPROM. It can be read and backed‑up using an EPROM burner but obviously, it will be next to impossible to unsolder it safely from the Main Board without taking a chance on breaking fragile PCB traces. My advice would be to just keep things as they are if you have v2.00, v2.01 or v2.02. I have seen a few rare cases on late production models which have socketed Quartz window EPROM's containing v2.02 firmware

Note: Unlike the W‑30, the S‑550 does not use ODD or EVEN EPROM's. Both IC#3 and IC#6 contain identical firmware code so you only need to backup one of the EPROM's and burn two of the same EPROM's when duplicating. Binary files for creating your own S‑550 EPROM's may be downloaded for free at the Synth & Sampler Binaries Webpage

To check the current firmware version of your S‑550 EPROM's, a monitor needs to be connected to the RGB port of the sampler

This is a list of all the S-550 EPROM firmware versions I have found in the wild

W‑30

Every W‑30 I have ever seen (early and late production models) have both EPROM's IC#19 (EVEN) and IC#20 (ODD) socketed so they are much easier to work with. Also, I've never seen any version other than v1.03. The only real need to make copies of these two EPROM's would be to have a backup available in the event the electrons deplete over time. For more info about electron depletion, see the EPROM Quick Start Guide

To check the current firmware version of the W‑30 ROM's, power on the sampler while holding down the [ F1 ] button

A message similar to the following will be displayed:

W‑30 Custom Wave ROM's

Special Thanks go out to Ishibashi Hisao and Bernd Brüning for all of their hard work on this very cool and FREE W‑30 upgrade. It replaces the two default Wave ROM's with new code on the factory Wave ROM IC's and contains 32 new Wave samples. Vintage Drums, Oberheim, Moog, Juno and several others are included. For more information, see this YouTube video

Installation Instructions:

S‑50 Service Information Sheets For Roland Engineers

Factory supplied info for repairing S‑50 hardware and software bugs

S‑50 Service Information Sheets

S‑50 Service Information Sheets

Main PCB Board Assemblies And Power Supplies

S‑550

There are four different models of the S‑550 sampler. Each one uses a different transformer (110V, 117V, 220V or 240V). The DIY's shown above were installed and tested on five different S‑550 samplers. Four of the models tested use the 117V transformer and the fifth uses a 240V transformer. 117V And 240V transformer systems use identical Power Supply Board Assembly PCB's. Main CPU Board Assembly silkscreen part numbers on the five models tested were

W‑30

There are two different models of the W‑30 sampler each using a different Power Supply Board (110V/117V & 220V/240V). The DIY's shown above were installed and tested on two W‑30 models using only the 110V/117V transformer model. The Main CPU Board Assembly silkscreen part numbers on both models tested was

It's interesting to note that the 110V/117V samplers (W‑30, S‑330, S‑750, S‑760 and SP‑700) all use the identical Power Supply Board. If you find yourself in a pinch and can't find a replacement power supply, one option might be to buy a "broken" sampler on eBay (i.e. one with a broken floppy drive, broken LCD, etc...) which has the same model power supply inside... provided it powers on, of course :^)

100V / 117V Power Board ‑ Roland P/N: 22443588 / MSA817

220V / 240V Power Board ‑ Roland P/N: 22443589 / MSA818

The schematic for this power supply is absent from the W‑30, S‑330, S‑750, S‑760 and SP‑700 Service Notes. A stripped down schematic and component layout does appear in the S‑770 Service Notes. However, there are no component values listed... only the PCB silkscreen numbers. From my experiences, the most common failure with this PSU are defective electrolytic capactions which leak fluid over the years. A list of the original electrolytic capacitor values and locations for a 110V / 117V PSU is here. If it's not an easy fix due to failing capacitors, this model is extremely difficult to repair because TDK took extra precautions to protect their design by encasing some of the circuitry inside a layer of blue polyresin. Thus, some of these components can't be replaced or even identified. Thanks soooooo much TDK

W-30, S‑330, S‑750, S‑760 and SP‑700 PSU's

I've been replacing all of my S‑760 PSU's with a Mean Well RPT-60C. It's a medical grade PSU and is only $25. Ray Bellis has designed a quality 3D bracket which is a highly recommended add‑on because this new PSU uses a live heat sink. The 3D bracket adds an extra level of safety. I have not installed the 3D bracket on the W‑30, S‑330 or SP‑700 yet so I'm unsure of the dimentions. Please verify before attempting to install in those models. Installation instructions for the S‑760 can be found at this link

There is also an excellent eBay store called scsi-connector which sells drop‑in PSU solutions and other DIY components for the S‑Series and W‑Series samplers. Check them out here

Spare Parts Cross Reference Chart

I've compiled a small cross reference chart which is useful for matching duplicate spare parts on Roland synths and samplers. I use this list to find spares on broken equipment bargains found at eBay auctions. I just bought an S‑220 for only $23 which has enough spare parts for 19 different Roland synths and samplers. Gotta love eBay!

Spare Parts Cross Reference Cart

Spare Parts Cross Reference Cart

Favorite DIY Tools And DIY Vendors

Tips For DIY Freaks Who Like To Save $$$. I picked this selection of gadgets and vendors because of the extremely LOW cost. I use everything shown here almost every day and highly recommend each one

Favorite DIY Tools And DIY Vendors

Favorite DIY Tools And DIY Vendors

Issue: Screen shaking or rolling around

TROUBLESHOOTING

- If you experience problems with a rolling or shaking screen as seen here to the right ➛ ➛

- With no OSD menu showing on the monitor, press the "SW" button three times

- This will advance and reset to the RGBS Video Mode (15-Pin VGA)

- With no OSD menu showing on the monitor, press the "SW" button three times

- If the screen continues to roll or shake, reset the GBS-8200 board

- With no OSD menu showing on the monitor, press and hold "DOWN/AUTO" for 5 seconds

- This resets the board to RGBS Video Mode

- (If not, press the "SW" button until the RGBS Video Mode returns)

- With no OSD menu showing on the monitor, press and hold "DOWN/AUTO" for 5 seconds

- NOTE: I have noticed that this shaking and rolling behavior is caused when removing the GBS‑8200 from an S‑50/S‑550/S‑330 and plugiing it into an S‑760 or vice versa

If you end up getting lost and venture into the cryptic Chinese menus by mistake, the quick route to get English displayed is made by pressing:

MENU > UP > MENU > UP > UP > MENU > MENU

Other menu button functions (with no OSD menu showing on the monitor)

Auto‑Scan: DOWN/AUTO

Reset The Board: Press and hold DOWN/AUTO for 5 seconds

Video Mode‑Select (RGBS / RGBHS / YPbPr): SW (RGBS = 15‑pin VGA connector)

This video board is very easy to use. If you need additional menu info and technical specs, download the GBS-8200 Operation Manual at this link

If this video board will be used with an S‑50 or S‑330, an inexpensive metal housing is recommended to keep the static sensitive components safe. I use a Hammond 1599DD aluminum enclosure (normally used as a guitar pedal case). These protective enclosures are readily available from Tayda Electronics here. If this is to be used with an S‑550 and there is no HD5‑IF SCSI Interface Card installed, you can do what I did and take advantage of the empty space on the underside. Place the video board inside the sampler like so...

$20 (USD). Now that's the kind of DIY I like... nice and inexpensive!

If needed, here is some more detailed info;

I tested the GBS‑8200 video board with a Sharp LL‑T15A4‑B 15" LCD Flat Screen VGA Color Monitor (manufactured in 2003 ‑ specs) and a Dell E176FP 17" LCD Flat Screen VGA Color Monitor (manufactured in 2006 ‑ specs). In addition to a standard 15‑pin VGA Out connector, there is also a 12‑pin socket (P12) on the GBS‑8200 video board which provides a video output signal for R, G, B, VSYNC, HSYNC, and GROUND. If you have an older style monitor like a CGA, EGA, or RGB, this extra 12‑pin connector might be able to adapt to those older style monitors by using a different connector arrangement. For this DIY, the included 8‑pin connector (P11) with six wires was used. You might be tempted to use a tap off of the main S‑550 circuit board to supply power for the GBS‑8200 video board. Don't do it. Ordering a replacement circuit board for vintage gear like the S‑550 is not an option. Play it safe and stick with a cheap external power supply. An external power supply will also help to isolate any hum the GBS‑8200 video board might introduce into the S‑550 audio circuit

Old RGB Monitors

Some of the older RGB color monitors that work with the Roland S‑50, S‑330, S‑550, S‑750, S‑760 and S‑770 use an oddball 8‑pin rectangular female connector (the official name for this connector is "SMK EIAJ 8‑Pin Female VTR Connector"). The color monitors distributed by Roland were P/N#: CC‑121 and P/N#: CC‑141. Similar RGB monitors were Amdek Color-II, Taxan RGB Vision-I, II & III and Sony Trinitron KV-1311CR. The cable needed for use with these old monitors is very difficult to find. Roland manufactured this cable with a rectangular male connector as P/N#: RGB‑25N

If you want to build your own cable, the cost to get all the parts (not including shipping) is about $40 (USD)

RGB‑25N DIY Cable Parts, Vendor Links, Instructions & Wiring Diagrams

RGB‑25N DIY Cable Parts, Vendor Links, Instructions & Wiring Diagrams

Partial List Of Monitors With An 8-Pin Digital RGB Input Connector

Partial List Of Monitors With An 8-Pin Digital RGB Input Connector

Two popular RGB monitors of days gone by were the Atari SC1224 and SC1435. These monitors used a strange 13‑pin connector. If you want to build your own cable, the cost to get all the parts (not including shipping) is about $35 (USD)

Atari SC1224 And SC1435 DIY Adapter Cable Parts, Instructions & Wiring Diagrams

Atari SC1224 And SC1435 DIY Adapter Cable Parts, Instructions & Wiring Diagrams

How To Share 1 Monitor With 2 Or More Roland S‑Series Samplers

If you have 2 or more Roland S‑Series Samplers, this inexpensive DIY is for you. Complete plans are contained in this PDF file

S-50_S-550_A-B_Switch-Box_DIY

S-50_S-550_A-B_Switch-Box_DIY

Using A Non‑Roland Mouse With The S‑550, S‑330 And S‑7xx Samplers

NOTE: The S‑50 will not work with any type of mouse. The EXT CONTROLLER port on the back of the S‑50 will only work with the optional DT‑100 Digitizer Tablet. If you plug a mouse into the EXT CONTROLLER port, you run the risk of causing a short circuit in the sampler. Likewise, if you plug a non‑Roland mouse into the EXT CTRL port on the S‑550, S‑330, S‑750, S‑760 or S‑770, you run the risk of causing a short circuit. If this happens, see info about replacing the PICO® fuse at the section on this webpage called Mouse Or RC‑100 Is Unresponsive, Intermittent Or Not Working

After losing bid after bid on expensive MU‑1 and MSX mice at eBay, I decided to purchase a KMTech PS/2 to MSX mouse adapter instead. It works flawlessly with my S‑550 and S‑760. The adapter is very small at 63mm x 19mm x 13mm. Compared to the price of a used MSX mouse, this clever adapter board is a bargain at $31 (USD) + shipping. The overseas shipping to the USA was amazingly fast at only 6 business days! The seller is kevinmount* who has a 100% Feedback Rating on eBay

* The item was PS/2 to MSX Mouse Adapter and was purchased from kevinmount

Ship time: 6 days from United Kingdom to the USA

The big advantage this adapter has over an MU‑1 mouse is that if the PS/2 mouse goes bad, a replacement is inexpensive as opposed to finding another expensive MU‑1 mouse on eBay. Plus, every MU‑1 or MSX mouse I've seen for sale on eBay is being sold as a used item and is already 30+ years old. I've had excellent results using a WYSE PS/2 (P/N: 770510‑21L / LED Optical Type) and a DELL (P/N: M-S34-6MD / Ball Wheel Type). It's recomended that when using a LED Optical Type mouse, do not use a mousepad with complex patterns. Use one with a solid color or the mouse pointer will jump around the screen

|

Not every PS/2 optical mouse is created equal. A majority of the low quality, no brand name models will not work. The name brands I've received positive feedback from website visitor eMails are WYSE, DELL, COMPAQ and (of course) IBM |

My only complaint about the board is that it needs some type of a cover. My solution was to wrap everything with black electrical tape. I can't stand to have an exposed circuit board with static sensitive components glaring at me. It goes against everything I was taught about electronics

|

🚫

🔌 💥 |

It is very important to note that S‑50, S‑330, S‑550, S‑750, S‑760 and S‑770 samplers are electrical dinosaurs from the 1980's. They were not designed with Plug & Play technology. Never "hot plug" an external device into these samplers because there is always the risk of blowing up the PICO fuse... or worse. It's even more dangerous for the S‑760 because there is no PICO fuse and no circuit protection for the EXT CTRL mouse port. Always ensure power to the sampler is turned off before connecting a Mouse, Hard Drive, ZIP Drive, CD‑ROM... anything (the only exception would be USB sticks (GOTEK) and microSD cards (SCSI2SD/ZuluSCSI) since these new devices already have built‑in circuit protection. And remember that the S‑50 will not work with any type of mouse. If you plug a mouse into the EXT CONTROLLER port, you run the risk of causing a short circuit in the sampler |

🚫

🔌 💥 |

2‑Prong Power Cable Replacement DIY

Tired of always looking for that oddball 2‑Prong AC power cable? Do something about it. Here's a super simple mod that will let you use the more common 3‑prong AC cable with your Roland sampler. The cost for parts was less than $1. In addition to always being able to find the right AC cable, this mod adds ground circuit protection. Why is that important? Just ask several S‑50, S‑550, W‑30 and SP‑700 owners who connected their sampler to an ungrounded mixing board. The audio output transistors on their samplers were toasted to a crisp!!!